Most Expensive Part of electric vehicle (EVs)

MOTORS

Cheaper & Smaller Motors

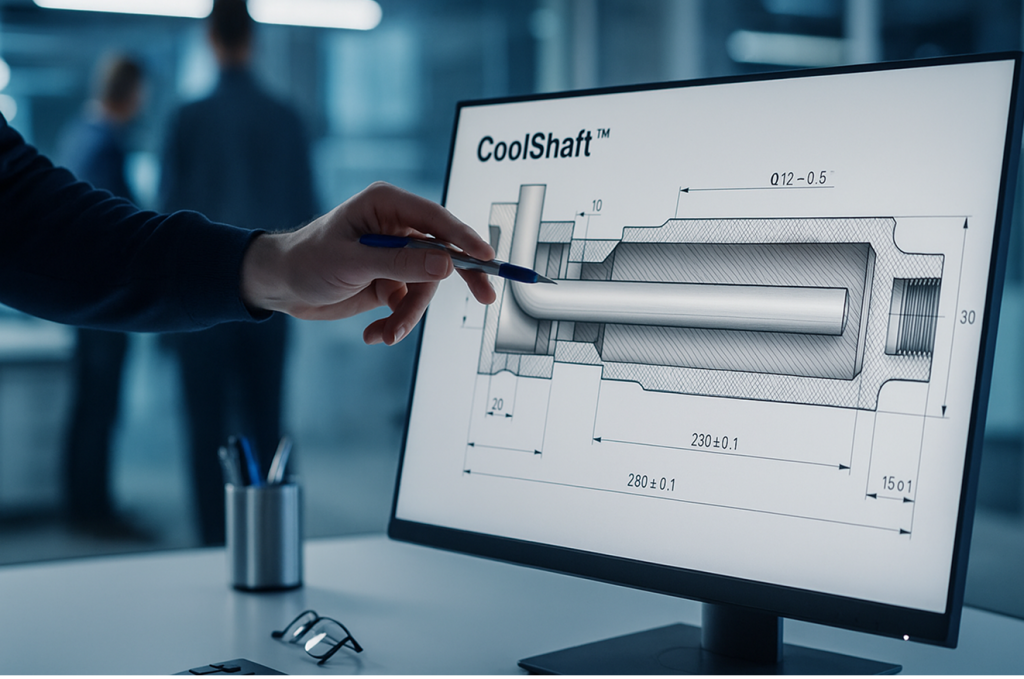

Coolshaft™

Rethink the Shaft,

Reinvent the Motor

We help you turn your motors into

Compact Cheaper Greener

Built to cool, Engineered to Lead

Coolshaft™

No Need for

Clean-sheet Design

Unlocking the

hidden potential

Extract 50% more continuous power out of your conventional motors. Plug and Play no need for clean sheet design.

50% less weight and length, increased efficiency & increased range as well as lower operating costs – Perfect for Hybrid – no need for platform redesign!

Reduce the size of electric vehicle (EV) motors without sacrificing continuous power

Reduce the need for rare earth magnets – enhance material security.

Convert continuous power gain to cost reduction – smaller, more compact motor, less expensive magnets

Reduce the embodied emission of conventional motors by 50%.

Use dysprosium free magnets – 40% cheaper

Enabled by our patented rotor cooling technology, Nuclear industry grade leak proof system, & proprietary manufacturing process.

Reduced costs, increased performance, smaller, lighter motors

Enables motor downsizing to fit existing engine bay constraints – hybrid without platform redesign

Reduce the wight and Size of Motors from air taxis and large drone – dual application

More power or downsized motor for lower cost and more payload capacity

Liquid cooled motors for maximum performance, compactness and reduced costs.

Electric motors have been around for two centuries; however abundance of space and materials have stunted their development.

With the advent of electric cars, mass automation and general electrification of mechanical work, it is essential to extract the maximum performance from our current materials. We have all of the technologies and materials to transition from fossil fuels now without economic punishment. Instead of focusing on ‘cool’ technologies that at best take decades to implement or at worse question the lows of thermodynamics, we focus on ‘cooling’. We have the opportunity to make significant changes today instead of waiting for the ‘unknown perfect solution’.

Making highly efficient, sustainable yet economically viable motors is not a simple task. We need to account for every gram, performance, topology, thermodynamic behaviour and performance.

Our goal is smaller motors, bigger future – We have a clear roadmap from rare-earth reduced conventional motors to low cost, globally accessible rare-earth magnet free power.

Our vision – our cooling systems in every EV motor, 1 billion electric vehicles by 2040.

Our CoolShaftTM Technology is easily accessible and can be produced anywhere in the world without the need for retooling. 80%+ of our CoolShaftTM parts are commonised.

CoolshaftTM is designed to be applicable to 95% of the motors in the market without requiring changes to the design (plug & play). It is designed with cost effective scalability & manufacturability as its corner stones. The CoolshaftTM is a modular, retrofit friendly rotor cooling system, hence eliminating the need for retooling & maintaining low costs. It is compatible with current motor architectures, enabling performance gains without the costly need for clean-sheet-design.